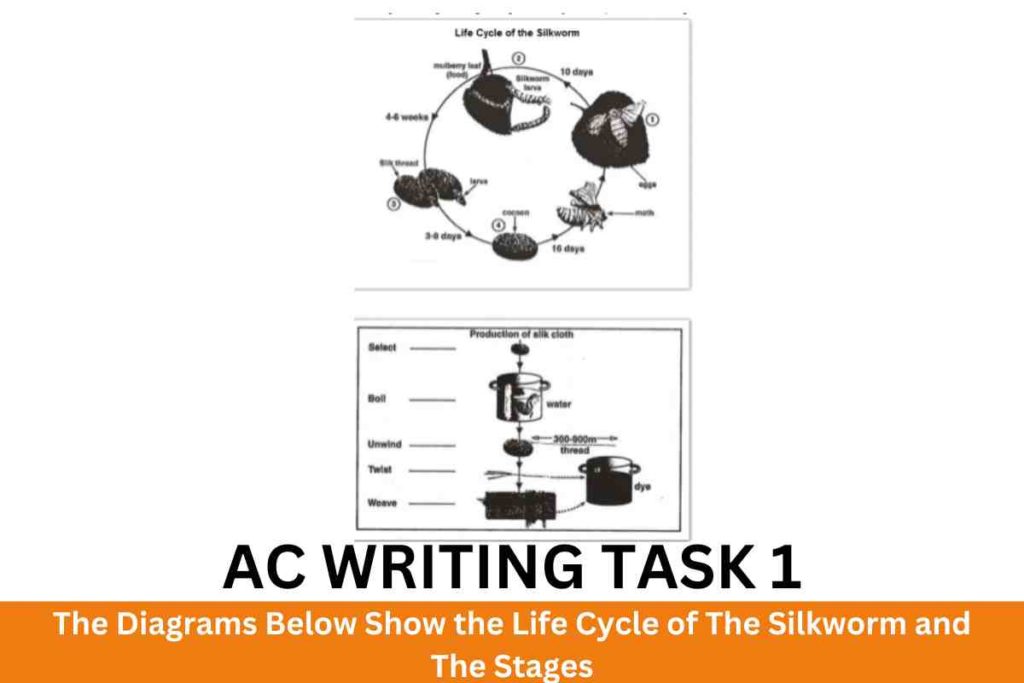

Sample 1:-The Diagrams Below Show the Life Cycle of The Silkworm and The Stages

The diagrams depict the life cycle of silkworms and the steps in the manufacturing of silk cloth.

Overall, the life cycle of the silkworm takes approximately ten weeks, while the production of silk cloth requires five stages.

When a silkworm lays the eggs, it takes ten days to develop into a larva. This larva feeds on mulberry leaf as a source of nutrition. The next phase would be maturing into silk thread which takes around 4-6 weeks. After a duration of 3 to 8 days, the cocoon is formed, which metamorphoses into a moth in a period of 16 days.

The silkworm is carefully selected and put in a pot with boiling water, which is then taken to the next stage of unwinding; it consists of 300 to 900 meters of thread. The next stage is twisting, where the threads are then twisted and weaved before putting in a container to be dyed.

Sample 2:-The Diagrams Below Show the Life Cycle of The Silkworm and The Stages

The following images depict the production of silk fabric and the formation of silk material biological from the initial stage, respectively.

Overall, there are four major stages wherein the silk material is obtained. In the first stage, the eggs are laid by the bee, which eventually takes ten days to grow into a larva, where it derives the food from the mulberry leaf.

From here, it grows through a period of 4-6 weeks to form silk thread and covert into a larva and the final stage, where the cocoon grows into of few days, approximately 3-8 days, and lastly, the moth. This has been a complete range of stages.

Coming to the mechanical production of cloth. It begins with selecting the finest thread and then boiling in water until the thread is approximately 300m and above; after several spins, it is waved in a bundle. It does not end here, but after immersing the product in a suitable dye to give the rich color and finishing touches, the fabric is ready for use.

Pages Content